ETher NDE

News

Latest news and information from ETher NDE

ETHER NDE booked to attend BINDT Aerospace Event in April 2022.

January 2022

ETher NDE will attend the BINDT Aerospace Event which will take place from 6-7 April at the BAWA Centre, Filton, Bristol. This is the only event in the UK dedicated solely to NDT in Aerospace.

ETHER NDE Festive Season Opening Times 2021-2022

December 2021

Wishing you all a Merry Christmas and a very happy and healthy New Year for 2022.

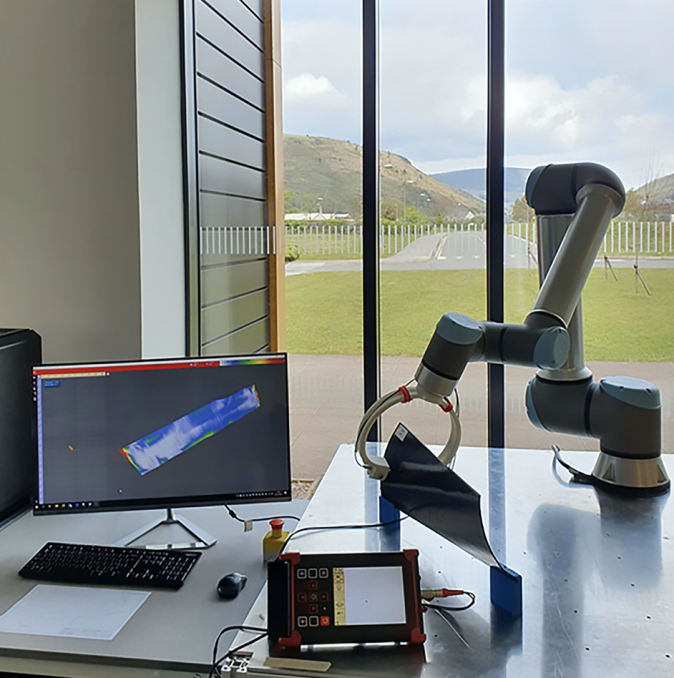

ETher NDE collaborate on the Innovate UK project for the Eddy current inspection of carbon fibre.

December 2021

"CFlux" is a project for the Eddy current inspection of Carbon fibre raw materials and cured parts in the Aerospace industry.

Restructure & Mezzanine Project making swift progress.

October 2021

September 2021 sees the start of new facility development at Ether NDE