Probes/Accessories

Thread Inspection (PT)

Thread Inspection Probes are designed for use in the inspection of internal and external thread sections.

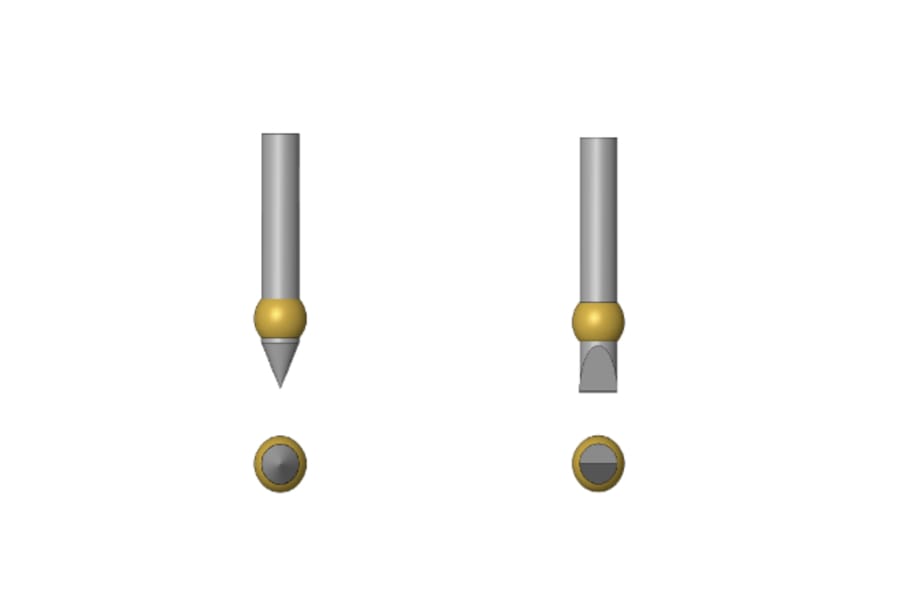

Chisel and pointed tips make them ideal for detecting cracks propagating in the root areas.

Key Features

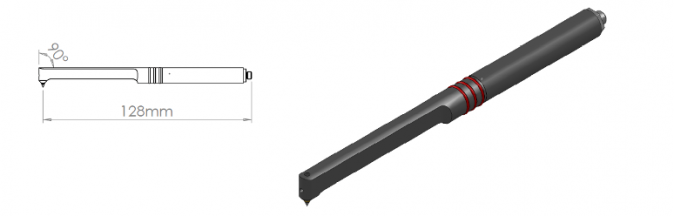

- Straight Tips ideal for extrnal threads (bolts)

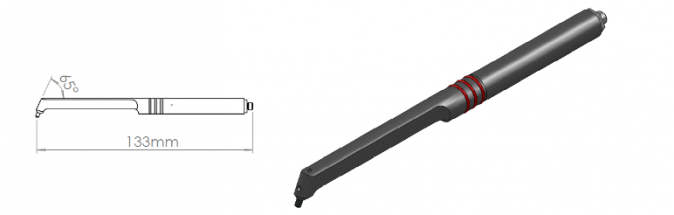

- 90 degree crank tips designed for external and internal threads (bolts and nuts)

- 65 degree crank probe tips available, ideal for internal threads (nuts)

- Used on Fe & Nde applications

- Pointed and chisel tips available through out

Saddle & Plug Thread Inpsection Probes (made to order)

Threaded sections can be inspected using a dedicated probe which can be supplied to fit either external or internal threads precisely. External threads can be inspected with a Saddle probe with a thread cut into the concave surface. The coil is fitted into the thread section to allow inspection to be carried out with very little probe wobble. A Saddle probe can be in the shape of a segment to screw along the thread like a nut.

Internal threaded sections can be inspected with a threaded Plug probe with a sensor moulded into the threaded area. The Plug probe is then simply moved along the thread, in the area of interest, to ensure 100% inspection.

Saddle and Plug probes are manufactured to order. A sample of the threaded section is usually required as a pattern for making probes.

Industries & Applications

- Aerospace

- Manufacturing

- Metals Processing

- Oil & Gas

- Power Generation

- Transport

- Thread Inspection

- Flaw Detection

Download our Probe Catalogue

If you know which probe type you are looking for you can send us the item details from the table below to make your order. Copy the product information below and email to sales@ethernde.com

- External (Straight) Probes

- 90deg Right Angle Probes

- Internal 65deg Probes

- Saddle and Plug - Thread Inspection Probes

- Leads

External (Straight) Probes (PTExxx)

90deg Right Angle Probes (PTRxxx)

Internal 65deg Probes (PTIxxx)

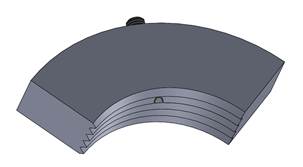

Saddle and Plug - Thread Inspection Probes

Threaded sections can be inspected using a dedicated probe which can be supplied to fit either external or internal threads precisely.

External threads can be inspected with a Saddle probe with a thread cut into the concave surface. The coil is fitted into the thread section to allow inspection to be carried out with very little probe wobble. A Saddle probe can be in the shape of a segment to screw along the thread like a nut.

Internal threaded sections can be inspected with a threaded Plug probe with a sensor moulded into the threaded area. The Plug probe is then simply moved along the thread, in the area of interest, to ensure 100% inspection.

Internal Thread Probe

External Thread Probe

Saddle and Plug probes are manufactured to order.

A sample of the threaded section is usually required as a pattern for making probes.