Products

WeldCheck 3

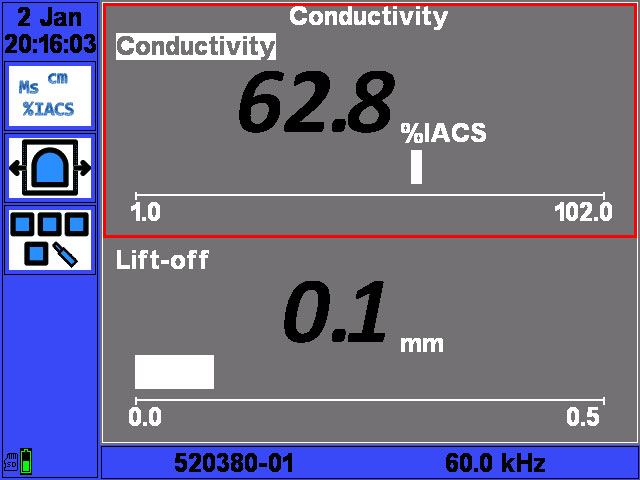

The WeldCheck 3 is a dual-frequency eddy current flaw detector, with conductivity, which means that the instrument can be used for dual and single frequency applications.

With improved physical and ergonomic design the WeldCheck 3 brings ETher NDE’s WeldCheck series right up-to-date. Based on in-field operator feedback and embracing the use of new case materials, the WeldCheck 3 delivers the end user enhanced ruggedness, a toughened screen, improved connector access and performance, combined optional features such as an encoder wheel.

The WeldCheck 3 is ideal and adaptable across an extremely wide variety of eddy current inspection tasks due to its superior performance; including weld inspection, surface defect detection and low frequency inspection of non-ferrous material.

Equipped for all environments

The WeldCheck 3 has been built to perform in some of the harshest working conditions in the NDT industry, including the rope access environment being lifted and lowered on ropes, knocked and dropped. With a rear foot stand and four harness attachment points, the WeldCheck 3 is adaptable to be used in various environments from the desktop, in the office, to the rigours of the job site. New over-moulded rubberised corners deliver enhanced impact protection and improved overall ruggedness. Internally the design is optimised to resist moist, tropical or salt-laden atmospheres, designed to meet IP64, performing reliably across inhospitable environments.

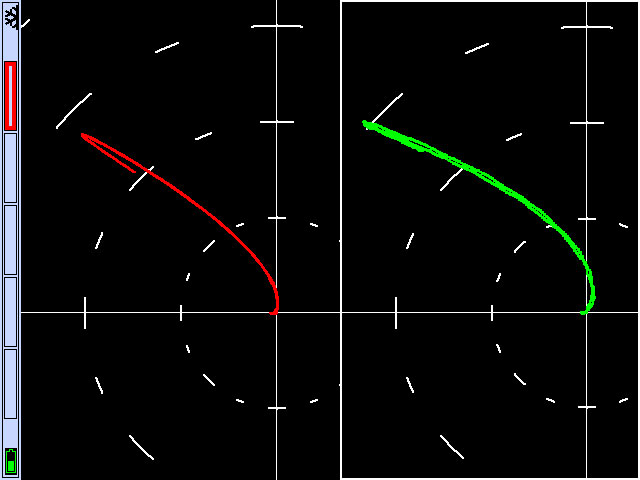

Toughened daylight visible, large colour screen

Being able to see the instrument screen clearly throughout all types of weather and light conditions is a top priority. The WeldCheck 3 has a fully daylight readable 14.5cm LCD Colour Screen of 640 x 480 pixels ensuring the operator has crisp presentation no matter what the working conditions are. The screen is further enhanced with a 2mm thick anti-reflective polycarbonate protector sheet which has excellent impact strength and added UV protection thanks to an anti-glare coating. The operator has the choice of configuring their own colour schemes and display types, further optimising viewing ability according to environmental conditions.

Extraordinary battery life

With more than 7 hours battery life, running with a 100kHz Weld Probe and maximum back-lighting, the WeldCheck 3 is an obvious choice when faced with a long day of Eddy Current NDT.

WeldCheck 3 Pipestand

Rugged Over-Moulded Design

New Software Feel & Functions

Top Panel Connectors, IP68 Rated

Harness Anchor Points

Built-in Tripod Mount

Industries & Applications

Advantages

- Lightweight, ergonomic, rugged portable design, weighing just 1.15kg (2.54lbs)

- Thumbwheel option for rapid menu navigation.

- Designed to meet the requirements on EN1711 & ISO 17643 "Eddy Current Examination of Welds by Complex Phase Analysis"

- Advanced features including Loop, Guides & Automatic Lift-Off Gain Correction.

- Toughened, anti-glare, large, crisp, daylight readable display, 145mm (5.7”).

- Designed to meet IP64, IP68 rated connectors.

- Over 7 hours battery life, fast 2.5 hrs charging time.

- 3 year standard warranty

- Optional EThercover extending warranty to 6 years.

Features

Industry standard probe connectors

All of the probe connections on the WeldCheck 3 are IP68 rated which further enhances the adaptability of this flaw detectors across industrial sectors. The WeldCheck 3’s connector panel is fitted across the top of the unit, making it ideal for rope access inspection and moving around on-site, working at height or with harnesses.

Probe socket LEMO 12-Way 2B (IP68): Absolute, Bridge, Reflection and Conductivity.

Probe socket LEMO Coax OO (IP68): Absolute.

Intuitive Software Menu and Icons.

The WeldCheck 3 menu system is simple and fast to navigate, with the ability to set up selectable soft key menu items to the sidebar as familiar icons for rapid function access and a quick “setting” menu for easy set-up, review and adjustment.

With four operator-selectable soft keys and a fifth slot for the last menu function used, technicians can quickly customise the system with their preferences.

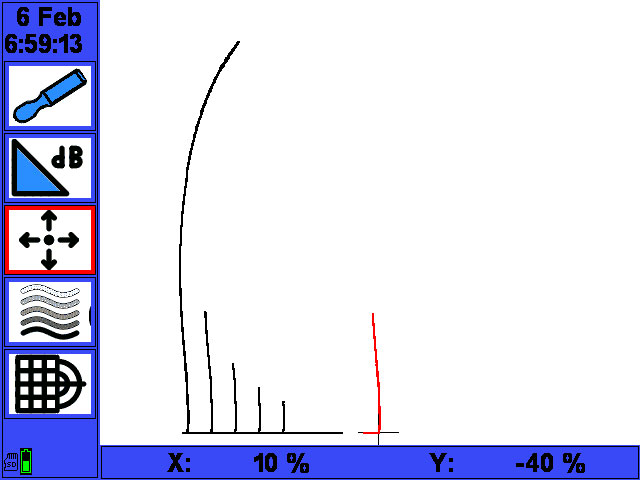

Innovative Loop Feature

Loop is a convenient way of capturing a short live repetitive signal and then optimizing the instrument settings through real time adjustments of the Phase, Gain, Balance, Filters and Display Configuration in order to simplify the task of optimising the parameters. The Loop function is excellent for calibration set up especially for setting a Dual Frequency mix.

“Editable Settings”

The Editable settings interface enables to operator to access and changes all the inspection settings via one screen. Working within this “screen” with the thumbwheel model option means changes can be made to the inspection set up very quickly.

Guides Feature

“Guides” allows the user to display a slide show that can be created easily with commonly used desktop software. The benefit of this feature is that instructions, tutorials and procedures for an inspection can be added to the WeldCheck3 very quickly and the NDT inspector can easily switch between the inspection itself and the “Guides” while performing a live test.

Automatic Lift Off Gain Compensation

The Lift Off Gain (LOGC) is a feature that automatically compensates the gain of the defect channel according to the paint thickness thus ensuring that a defect signal will appear the same height irrespective of the paint thickness.

Videos

Standard Kit

WeldCheck 3 Kit (Keypad Option) : KIWEL300

| Part Number | Item |

|---|---|

| IWEL300 | Instrument, WeldCheck 3, Dual Frequency (10Hz-20MHz), Portable Flaw Detector, Software & Manual on USB Stick |

| AWEL009 | Accessory, WeldCheck 3 - Lemo Type, Power Adapter + Input Plugs (UK, EU, US & Australia) |

| AWEL003 | Accessory, Adjustable Shoulder Strap, Padded with Quick-Release |

| AC006 | Accessory, Instrument Soft Carry Case |

| A090 | USB Cable, A to MIN B, 1 metre |

| 41242 | Quick Reference Card (A5) – WeldCheck 3 |

| ALLCX-M02-015A | Accessory, Lead, Lemo 00 to Microdot, 1.5m (Absolute) |

| ALL12-L04-015B | Accessory, Lead, Lemo 12 -Way - Lemo 4-Way (Bridge) |

| A439 | Split Rings - ID 25.00, Thickness 3mm, (SKU:NPS25) |

WeldCheck 3 Kit (Thumbwheel Option) : KIWEL300TW

| Part Number | Item |

|---|---|

| IWEL300TW | Instrument, WeldCheck 3, Thumbwheel, Dual Frequency (10Hz-20MHz), Portable Flaw Detector, Software & Manual on USB Stick |

| AWEL009 | Accessory, WeldCheck 3, Lemo Type. Power Adapter & Input Plugs (UK, EU, US & Australia) |

| AWEL003 | Accessory, Adjustable Shoulder Strap, Padded with Quick-Release |

| AC006 | Accessory, Instrument Soft Carry Case |

| A090 | USB Cable, A to MIN B, 1 metre |

| 41242 | Quick Reference Card (A5) – WeldCheck 3 |

| ALLCX-M02-015A | Accessory, Lead, Lemo 00 to Microdot, 1.5m (Absolute) |

| ALL12-L04-015B | Accessory, Lead, Lemo 12-Way - Lemo 4-Way (Bridge) |

| A439 | Split Rings - ID 25.00, Thickness 3mm, (SKU:NPS25) |

Accessories

| Part Number | Item |

|---|---|

| AAER005 | Hard Transit Case |

| AWEL010 | Protective Splash Case (keypad only version) |

| AWEL011 | Protective Splash Case (thumbwheel only version) |

| AWEL006 | External 8 x AA battery holder |

| ALL12-L04-015R | Accessory, Lead, Lemo 12-Way - Lemo 4-Way (Reflection Probes) |

| ALL12-L04-015B | Accessory, Lead, Lemo 12-Way - Lemo 4-Way (Bridge Probes) |

| ALLCX-M02-015A | Accessory, Lead, Lemo 00 to Microdot, 1.5m |

| ALLCX-B02-15A | Accessory, Lead, Lemo 00 to BNC, 1.5m |

Standard EC Weld Probe Package (KAWEL001)

Our standard Weld Inspection Package can be used across our range Eddy Current Flaw Detectors and those of our competitors. Designed and manufactured in the UK, our Weld Probes are of high quality build, with fast delivery times.

| Part Number | Item |

|---|---|

| PWM100S000 | Probe, Weld, Medium, Dia 16.00, 100kHz, Straight, Disconnect |

| PUB100K | Unshielded, Broad Band (paint), 100k (35kHz-250kHz), BNC |

| ATBW | Accessory, Test Block, Weld Probe, Ferrous (Steel EN1A) & 4 x 0.5mm Shims, 0.5, 1.0, 2.0mm slots |

| ALL12-L04-015B | Lead, Lemo 12-Way - Lemo 4-Way, 1.5m (Bridge) |

| ALLCX-M02-015A | Accessory, Lead, Lemo 00 to Microdot, 1.5m (Absolute) |

| AW003 | Accessory, Butterfly PTFE Tape (Pack 30) |

| AW002 | Probe Carry Bag |