Applications

Thread Inspection

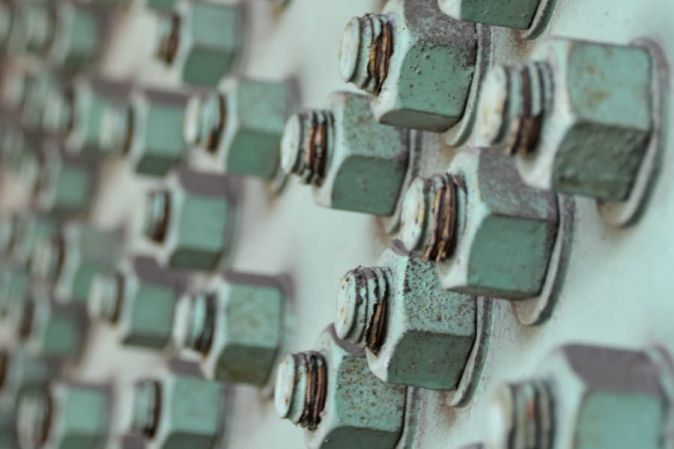

Common components in most of society’s critical infrastructure are bolts and threads, which require, as standard, regular integrity checks to ensure that they, and what they are “bolting together”, is fit for service and safe.

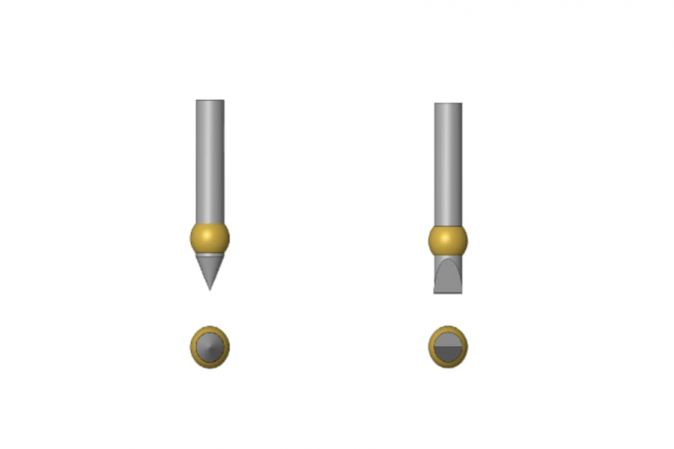

Eddy current inspections can be used to verify the quality or presence of a thread, verification of a component feature, or verification that an assembly is properly put together. Eddy current has proven to be a leading method for reliable and accurate thread inspection. EC Thread inspection can help to identify Thread damage, correct thread sizing, missing holes, short or broken taps. Component features eg splits and keeper grooves can also be inspected as can other thread-based parts that are part of an assembled product, where fatigue or damage could compromise production or the finished product's performance.

Related Industries

Related Industries:

Application Notes: