Products

ACE ACFMT

ACE: The Next Generation of Portable ACFMT Inspection Technology

ETher NDE’s ACE portable Alternating Current Field Measurement (ACFMT) instrument offers all the advanced capabilities of ACFMT NDT inspection technology in a lightweight, rugged, and easy-to-use package. With a selection of standard and bespoke probes developed in-house, ACE provides a versatile solution for a wide range of industrial applications, ensuring reliable and accurate inspection results every time.

- Lightweight and Durable: Designed for portability without sacrificing toughness, ACE is the ideal solution for on-site, single-operator inspections.

- ACFMT Technology: Based on eddy current principles, ACE induces small, uniform currents within the test material surface. It measures changes in these currents to detect and characterize surface-breaking defects, measuring the length and depth accurately.

- Comprehensive Reporting Software: ACE-R allows users to generate detailed inspection reports, including defect sizes, locations and test data. All scan data is stored for audit tracking and the software supports in-depth investigations and customized report generation.

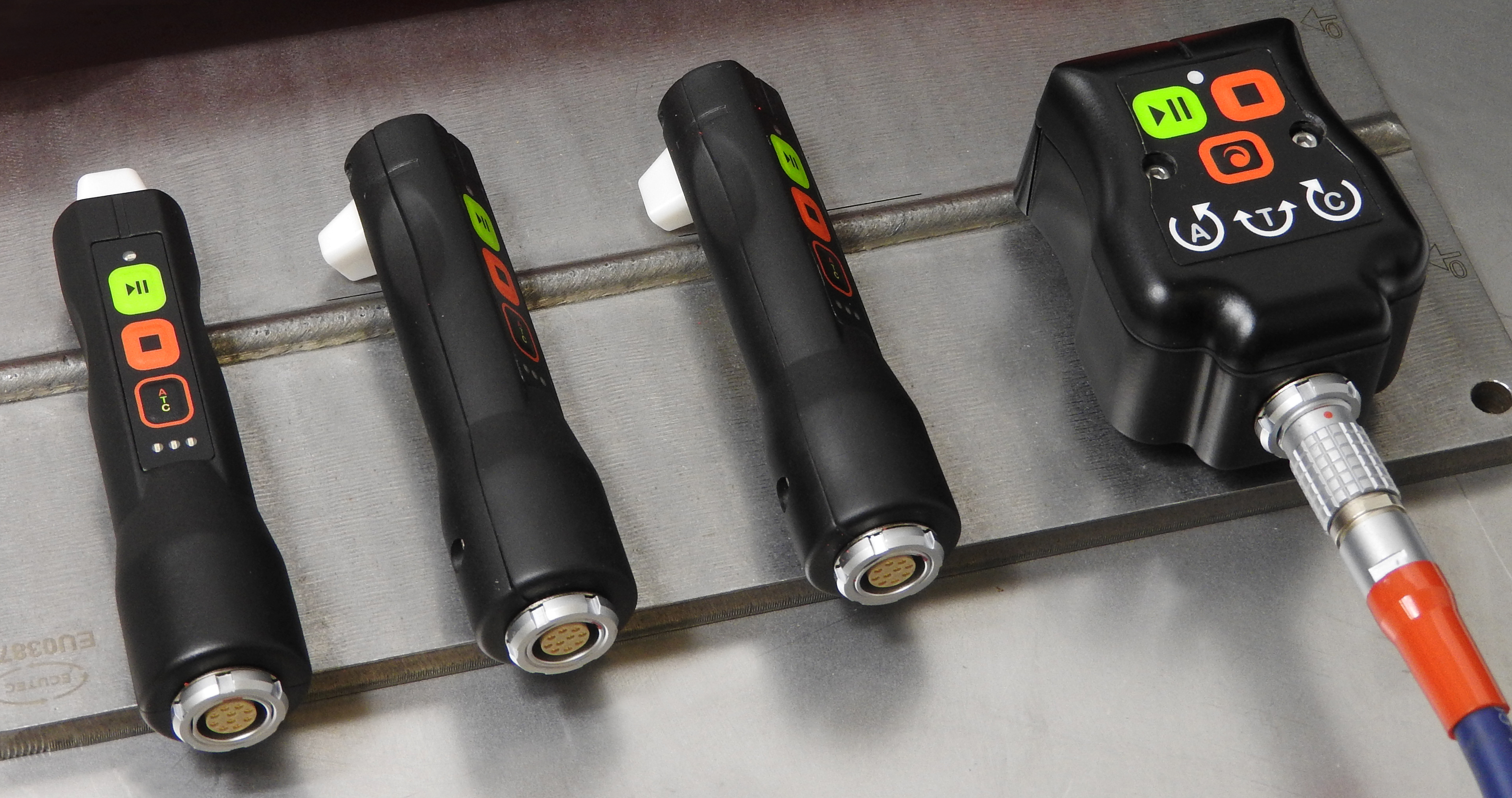

Versatile and Innovative ACFMT Probes

The ACE system includes a wide range of ACFMT probes, both standard and bespoke, designed for smooth repeatable inspections. Each probe is engineered with integrated "Start/Pause," "Stop," and "Change Direction" buttons, making them ideal for one-person operation. Key probe options include:

- Standard Weld Probes: Ideal for topside weld inspections, these probes feature large drive coils that are perfect for sizing deep defects. They are also suitable for general component inspections wherever access allows.

- Pencil Probes: For areas where the larger weld probe geometry doesn’t fit, the pencil probes are available in straight or right-angled nose configurations. These are perfect for accessing tight or challenging inspection areas and feature smaller drive inducers for improved performance, especially around plate edges.

Whether you need to inspect Ferritic or Austenitic welds, the ACE system supports 5 kHz probes for Ferritic Welds and 50 kHz probes for Austenitic welds, ensuring precise results across a wide range of materials.

Advanced Software for Seamless Inspections

ACE’s inspection software has been optimized to work alongside the hardware, making inspections simpler, faster, and more efficient:

- Real-Time Feedback: Probes provide live scanning status and configuration details, so you can monitor your inspection every step of the way.

- Audit Tracking & Data Storage: All scan data is stored for full audit tracking, ensuring that every inspection is thoroughly documented and easily accessible for later review.

- Custom Reports: The accompanying desktop software enables in-depth analysis of scan data and the creation of bespoke, client-specific reports, complete with defect sizes, locations, and detailed inspection data.

Effortless Reporting

Creating inspection reports is simple with ACE. With just a few key presses, you can quickly generate a report from any dataset. The final report includes:

- Location information

- Relevant data traces

- Defect sizes

- Notes entered during the inspection

Reports are available in both PDF and DOCX formats and include details on the probe and instrument used, as well as an inspector "sign-off" for verification.

ACE is used across a wide range of industries, offering reliable and efficient inspection solutions:

- Rope Access Inspections

- Weld Inspections

- Refinery Piping & Vessels

- Painted & Coated Structures

- Pipeline Welds

- Bridges & Infrastructure

- Offshore/Onshore Topside Structures

ACE ACFMT Probes

ACE ACFMT Probes face on

ACE Nanuk Pelicase

ACE ACMFT Standard kit & Nanuk Pelicase

ACE Pencil Probe on weld test plate

Industries & Applications

Advantages

- Lightweight, 1.4kg, ergonomic, rugged portable design - ideal for a single operator.

- Two probes are included in the standard kit, one weld and one pencil probe.

- Large 7" High-Contrast LCD weatherproof screen display ensures clear visibility in all lighting conditions, perfect for outdoor inspections in any weather.

- Long Battery Life: Extended battery performance supports 10 hours plus of operation in the field.

- No software licence fees.

- Standard 2 year warranty included.

- Optional EtherCover extending warrany to 5 years.

Features

- Quickly generate a report from any dataset which will include Defect Sizes and Location information, relevant data traces and inspection notes.

- Accompanying desktop software supports the operator and client further, with analytical functions to investigate scan data and create bespoke client/job focussed reports.

- ACE has been designed to meet the requirements of ASTM Standard Practice for Examination of Welds using the Alternating Current Field Measurement Technique (E2261-03), latest revision: E2261-17

Videos

Standard Kit

ACE Probes are not listed below, as part of the standard kit two Probes must be chosen and ordered separately from the Probe List, which can be found under the Accessories section below.

| Part Number | Item |

|---|---|

| IACF001 | Instrument, ACE ACFMT Portable Flaw Detector, Software & Manual on USB Stick |

| ALL10-L10-02-ACF | Accessory, Lead, Lemo 10-Way to Lemo 10-Way, 2m ACE, ACFMT, Top Side |

| AWEL009 | Accessory, Lemo Type, Power Adapter + Input Plugs (UK, EU, US & AUS) |

| AWEL003 | Accessory, Adjustable Shoulder Strap, with quick-release clips |

| A090 | USB Cable, A to MIN B, 1m (RoSH Compliant) |

| 41339 | Quick Reference Card (A5 Double Sided) - ACE, ACFMT |

| A439 | Split rings-Nickel Plated Steel Split Ring ID 25.00, Thickness 3mm, (SKU:NPs25) |

| ATBACFWCS | Accessory, Test Block, ACE, ACFMT, Weld Reference Standard 1 - ASTM E2261-17- c/s, Elliptical Slots, Two elliptical slots placed in the weld toe with dimensions: A = 50mm x 5mm, B = 20mm x 2mm, Carbon Steel |

| AC023 | Accessory, Instrument Hard Carry Case (ACE, ACFMT) (Standard) |

| A472 | ETher NDE Magnetic Ruler (45cms) |

| A501 | ETher NDE Microfibre Cloth 30x 20cm |

Accessories

(A Carbon Steel test block is included in the Standard ACE Kit and used with all 5kHz probes. If ordering a 50kHz probe, an Austenitic Stainless Steel test block must also be ordered, part no: ATBACFWSS)

| Probes |

|---|

| Part No. | Item |

|---|---|

| PACF05PTS | Probe, ACE, ACFMT, 5kHz (Ferritic), Pencil, Topside, Straight |

| PACF50PTS | Probe, ACE, ACFMT, 50kHz (Austenitic), Pencil, Topside, Straight |

| PACF05PTI | Probe, ACE, ACFMT, 5kHz (Ferritic), Pencil, Topside, 90 deg Inline |

| PACF50PTI | Probe, ACE, ACFMT, 50kHz (Austenitic), Pencil, Topside, 90 deg Inline |

| PACF05PTT | Probe, ACE, ACFMT, 5kHz (Ferritic), Pencil, Topside, 90 deg Transverse |

| PACF50PTT | Probe, ACE, ACFMT, 50kHz (Austenitic), Pencil, Topside, 90 deg Transverse |

| PACF05WT | Probe, ACE, ACFMT, 5kHz (Ferritic), Weld, Topside |

| PACF50WT | Probe, ACE, ACFMT, 50kHz (Austenitic), Weld, Topside |

| Probe Leads |

|---|

| Part No. | Item |

|---|---|

| ALL10-L10-02-ACF | Accessory, Lead, Lemo 10-Way to Lemo 10-Way, 2m ACE, ACFMT, Top Side |

| ALL10-L10-05-ACF | Accessory, Lead, Lemo 10-Way to Lemo 10-Way, 5m ACE, ACFMT, Top Side (Standard) |

| ALL10-L10-10-ACF | Accessory, Lead, Lemo 10-Way to Lemo 10-Way, 10m ACE, ACFMT, Top Side |

| ALL10-L10-20-ACF | Accessory, Lead, Lemo 10-Way to Lemo 10-Way, 20m ACE, ACFMT, Top Side |

| Test Blocks |

|---|

| Part No: | Item |

|---|---|

| ATBACFWCS | Accessory, Test Block, ACE, ACFMT, Weld Reference Standard 1 - ASTM E2261-17- c/s, Elliptical Slots, Two elliptical slots placed in the weld toe with dimensions: A = 50mm x 5mm, B = 20mm x 2mm, Carbon Steel |

| ATBACFWSS | Accessory, Test Block, ACE, ACFMT, Weld Reference Standard 1 - ASTM E2261-17- c/s, Elliptical Slots, Two elliptical slots placed in the weld toe with dimensions: A = 50mm x 5mm, B = 20mm x 2mm), Stainless Steel |

| Accessories |

|---|

| Part No: | Item |

|---|---|

| AC022 | Accessory, Instrument Soft Carry Case (ACE, ACFMT) |

Specification

| Probe Connector | 10-Way LEMO 2B |

| Frequency | 5kHz (Ferritic Welds) and 50kHz (Austenitic Welds) |

| Display/Screen | 7”, 800 x 480 pixels, WVGA, 24 bit RGB colour. |

| Removable Storage Data | 32GB micro SD |

| Outputs | PC Connectivity USB (Full PC remote control plus Real Time data) |

| Outputs | VGA 15-Way VGA output |

| Languages | English |

| Power On Self-Test | A “self test” on start-up is performed of external ram, accelerometer, Micro SD card, LCD screen buffer. |

| Batteries | Internal Lithium-Ion Rechargeable, 7.2V nominal @64Ah = 46.08 watt.hr |

| Running Time | 10 hours plus |

| Charge Time | 5hrs. (simultaneous charge and operation) |

| External | 100-240v 50-60Hz 30Watts |

| Connector | Lemo OS Hermaphroditic keying, half-moon insert (IP68) |

| Weight | 1.4kg (3.0 lb) |

| Size (w x h x d) | 282 x 171 x 66 mm (11.1 x 6.7 x 0.26 in) |

| Material | ABS /Rubber Polyurethanes |

| Operating Temp. | -20 to +60C (-4 to 140F) |

| Storage Temp. | Up to 12 months -20 to +35C (-4 to 95F) |

| IP Rating | Designed to meet the requirements of IP64 |

| Harness Points | 4 rugged corner harness points |

| Compliance | ASME, EN61010-1, CE |

Related Products

WeldCheck 3

More