Products

BonPEC

ETher NDE's innovative pulsed eddy current technology (PECT) solution.

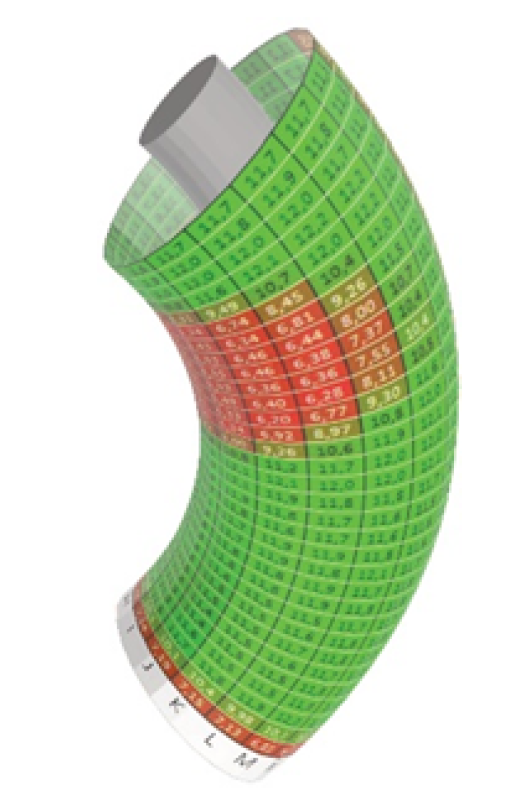

BonPEC delivers a non-intrusive electromagnetic technique based on Pulsed Eddy Current which allows detection, measurement and monitoring of corrosion in low alloyed carbon steel pipes and vessels through their insulations, coatings, paints, concrete fire-proofing or marine growth.

BonPEC does not require direct contact with the inspection target, nor cleaning or special preparation of the surface of the object to be examined, therefore no costly and unnecessary insulation removal is needed to perform PECT inspection, which delivers a considerable cost saving for the client.

PECT is the efficient and cost effective solution for the examination of insulated and corroded components and parts across the offshore industry and energy sector.

BonPEC software has been developed based on the way a typical NDT survey is performed. Initially one needs to know what needs to be investigated, which is represented by client and object parameters.

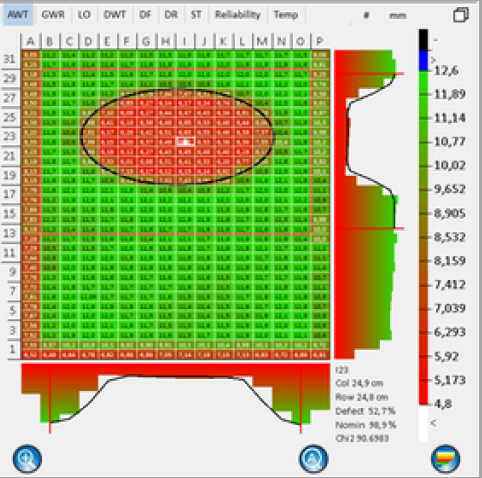

Important parameters are the type of object (pipe, plate or bend), the nominal wall thickness, the lift-off and the of cladding used etc. Based on this information and the experience of the operator, a suitable probe is selected and a suitable scan is defined. The BonPEC program gives tools to inspect, check, evaluate and report the measurement data.

BonPec Probe Range

BonPEC Screen Stand

BonPEC Kit

BonPEC unit Mounted with Screen

BonPEC Rugged Pelicase

Industries & Applications

Advantages

- State-of-the-art Pulsed Eddy Current Technology.

- Two probes as standard within the kit.

- Two screen display options.

- Lightweight adaptable system.

- NDT Inspection workflow based software delivering advanced PECT data analysis and evaluation.

- Standard set is splash water tight, salt and fog resistant, meets IP65.

- Insulation thickness <200 mm (probes dependant).

- Min. pipe diameter 50mm (2”).

- Temperature Range. -150°C to 500 °C.

- Intuitive software and advanced reporting features including Auto report generation, Graphs, 3D result projection on object model/photographs etc

- Applications include: In-Service Corrosion Monitoring, Splash Zone Inspection, Wall Thickness Monitoring and Inspection through Repair Wraps, Remaining Ligament Assessment through Corrosion.

- No hidden costs - all inclusive lifetime pricing means no annual software support fees.

Features

Inspection Ready

Probes

There is a range of probes to choose from in order to optimize the reliability of the results. For a large lift-off a larger probe is needed. Two probes are available as standard, P0.5 and P1.0, with other options available.

BonPEC probes are designed to minimize false readings, hence they are insensitive to metal objects near the probe, except for the object that is right below it. Due to magnetic field focusing, the probes are (within boundaries) insensitive to lift-off change, angle mis-match or variations of sheeting thickness

Software

BonPEC software has been developed based on the way a typical NDT survey is performed. Initially one needs to know what needs to be investigated, which is represented by client and object parameters.

Portable Power

Standard Kit

| KIPEC002 KIT, BonPEC, Pulsed Eddy Current (PEC) Instrument, Flaw Detector + 11.6" Rugged Tablet PC (Hot-Swap Battery 10 hour Battery, Touch Screen + Keys). |

|---|

| Part No. | Description |

|---|---|

| KIPEC002 | KIT, BonPEC, Pulsed Eddy Current (PEC) Instrument, Flaw Detector + 11.6" Rugged Tablet PC (Hot-Swap Battery 10 hour Battery, Touch Screen + Keys). |

| IPEC001 | Instrument, BonPEC, Pulsed Eddy Current (PEC) Instrument, Flaw Detector. |

| APEC001 | Accessory, BonPEC - Power Adapter + Input Plugs (UK, EU, US & Australia) |

| ALL08-L08-025-PEC | Accessory, Lead, Lemo 8-Way - Lemo 8-Way, 2.5m, BonPEC |

| PEC-P10-0-20 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 0-20mm |

| PEC-P50-25-100 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 25-100mm |

| RUGGED TABLET | 11.6" Durabook U11 Rugged Tablet, Windows 11 Pro 8GB RAM 256GB Storage + Power A487 Adapter (Hot-Swap Battery 10 hour Battery, Touch Screen + Keys) |

| AWEL003 | Accessory, Adjustable Padded Shoulder Strap Quick-Release Clips |

| AC026 | Accessory, BonPEC Hard Carry Case |

| 60130 | Software, BonPEC - Data Analysis, Storage & Reporting Software |

| A509 | USB LEAD - USB 2 Male Right Angled A - 6in - USB2 Male Right Angle B - , Ultra-thin Cable Dia 3.2mm, (USB Custom Cable - AL/BL/6in - REQ#17417) |

| A504 | USB LEAD - USB 2.0, Male USB A to Male USB B, 1.8m |

| KIPEC003 KIT, BonPEC, Pulsed Eddy Current (PEC) Instrument, Flaw Detector, 14" Rugged Notebook (Hot-Swap Battery 10 hour Battery, Touch Screen + Keys). |

|---|

| Part No. | Description |

|---|---|

| IPEC001 | Instrument, BonPEC, Pulsed Eddy Current (PEC) Instrument, Flaw Detector. |

| APEC001 | Accessory, BonPEC - Power Adapter + Input Plugs (UK, EU, US & Australia) |

| ALL08-L08-100-PEC | Accessory, Lead, Lemo 8-Way - Lemo 8-Way, 10m, BonPEC |

| PEC-P10-0-20 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 0-20mm |

| PEC-P50-25-100 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 25-100mm |

| A393 NOTEBOOK | Getac S410 G5, i5-1340P, 8GB RAM, 256GB PCIe SSD, , FHD & Touchscreen (1920x1080), (Without Webcam), , Windows 11 Pro (GETAC: ST2D5AQ3SDXX) |

| A394 BATTERY PACK | Main battery, Notebook, GETAC S410, Battery Type : Lithium-ion 6 cells, 74.5WH, Nominal Voltage : 10.8V, Capacity : 6900mAh, (GETAC: GBM6X6) |

| AWEL003 | Accessory, Adjustable Padded Shoulder Strap Quick-Release Clips |

| AC026 | Accessory, BonPEC Hard Carry Case |

| 60130 | Software, BonPEC - Data Analysis, Storage & Reporting Software USB LEAD - USB 2 Male Right Angled A - 12in - USB2 Male Right Angle B - |

| A503 | Ultra-thin Cable Dia 3.2mm |

| A504 | USB LEAD - USB 2.0, Male USB A to Male USB B, 1.8m |

Accessories

| Leads (Compatible across both Kit Configurations) |

|---|

| ALL08-L08-025-PEC | Accessory, Lead, Lemo 8-Way - Lemo 8-Way, 2.5m, BonPEC |

| ALL08-L08-050-PEC | Accessory, Lead, Lemo 8-Way - Lemo 8-Way, 5.0m, BonPEC |

| ALL08-L08-100-PEC | Accessory, Lead, Lemo 8-Way - Lemo 8-Way, 10.0m, BonPEC |

| ALL08-L08-200-PEC | Accessory, Lead, Lemo 8-Way - Lemo 8-Way, 20.0m, BonPEC |

| BonPEC Probes (Compatible across both Kit Configurations) |

|---|

| PEC-P0-0-7 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 0-7mm, Nominal Lift Off: 0mm, Wall Thickness at Nominal Lift Off: 1-10mm |

| PEC-P10-0-20 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 0-20mm, Nominal Lift Off: 10mm, Wall Thickness at Nominal Lift Off: 2-20mm |

| PEC-P30-15-60 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 15-60mm, Nominal Lift Off: 30mm, Wall Thickness at Nominal Lift Off: 2-30mm |

| PEC-P50-25-100 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 25-100mm, Nominal Lift Off: 50mm, Wall Thickness at Nominal Lift Off: 3-30mm |

| PEC-P100-50-150 | Probe, BonPEC, Pulsed eddy Current (PEC), Lift Off Range: 50-150mm, Nominal Lift Off: 100mm, Wall Thickness at Nominal Lift Off: 3-30mm |

| Durabook U11 Rugged Tablet Accessories: |

|---|

| A490 U11 | Screen Protector Film (APC GROUP: DURABOOK/DPFU1X) |

| A491 U11 | Spare Stylus & Tether (APC GROUP: DURABOOK/DMSTXX) |

| A492 U11 | Rotation Hand Strap (APC GROUP: DURABOOK/DMRHUX) |

| A493 U11 | Shoulder Strap (4 Point) - (APC GROUP: DURABOOK/DMS4UX) |

| A494 U11 | Shoulder Strap (2 Point) - (APC GROUP: DURABOOK/DMS2UX) |

| A495 U11 | Battery Charger - 2 bays - (APC GROUP: DURABOOK/DC2U1C) |

| A496 U11 | Spare 65W AC Adapter with power cord / RoHS Compliant / QA Approved (APC GROUP: DURABOOK/DAA6XC) |

| A498 U11 | Optional hi-cap battery Li-Ion 7.6V, 9600mAh, 20 hours |

| A499 U11 | Spare Main Battery |

| Notebook - Getac S410 G5 Accessories |

|---|

| A394 BATTERY PACK | MAIN BATTERY - NOTEBOOK - GETAC S410, Battery Type : Lithium-ion 6 cells, 74.5WH, Nominal Voltage : 10.8V, Capacity : 6900mAh, (GETAC: GBM6X6) |

| A466 BATTERY | MULTIMEDIA BAY BATTERY, Battery Type : Lithium-ion, 6 cells, 46.6WH, Nominal Voltage : 11.1V, Capacity : 4200mAh, (GETAC: GBS6X1) |

| A527 | Getac 65W AC Adapter with Power Cord (UK) (GAA6K5) |

| A528 | Getac 65W AC Adapter with Power Cord (US) (GAA6U5) |

| A529 | Getac 65W AC Adapter with Power Cord (EU) (GAA6ES) |